investment casting is one of the earliest forms of producing precision parts in metal. It is likewise known as the shed wax approach. The procedure involves producing a wax pattern which is essentially a replica of the wanted part in steel. The pattern is framed in a ceramic product and after that got rid of or "lost" via the intro of warm. The mold and mildew will then have thawed steel put into the opening. When the mold is escaped from the strong steel, the casting is available for use.

The history of this process goes back countless years. Initially bees wax was developed into the preferred shape and then covered in clay. Steel was melted utilizing bellows and also coal fire. The process was used to form shapes such as idols, fashion jewelry, as well as art. As time proceeded, developments were made in the accuracy of the materials and procedures to the point where incredibly foreseeable results might be achieved. Dental professionals were several of the initial individuals of Investment casting on a more commercial level, making use of the procedure to produce dental fillings to be used inside the mouths of people.

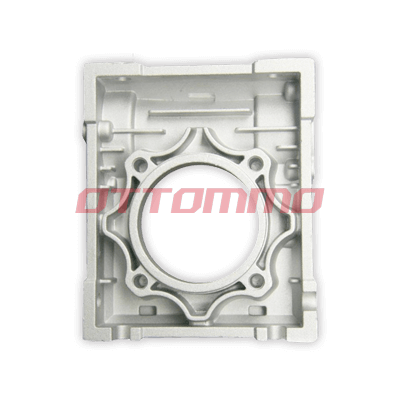

Innovations in the pattern making, wax, refractories, as well as melting devices have actually led to procedures that can hold extremely limited dimensional residential or commercial properties. Modern investment castings generally hold measurements that are gauged by a few thousandths of an inch per inch. This allows parts to be made that usually can be made use of directly from the manufacturer without subsequent machining. Worst cases allow the components to be near internet form, which minimizes the quantity of managing and refining to be completed on the casting. Individuals of these casting procedures can likewise release the process to develop components that can be poured in hundreds of various materials including steel, non-ferrous products, duplex alloys, aluminum, iron, and also more.

Applications of financial investment spreading have expanded enormously during contemporary times. Financial Investment Casting are used to create elements in aerospace, transportation, product handling, pump and also shutoff, food processing and more. Sculptures as well as initial art also utilize financial investment casting to create a steel variation of a musician development. Investment casting is likewise utilized to develop medical carries out and parts made use of inside the human body.

For further informations please visit here : OTTOMMO CASTING