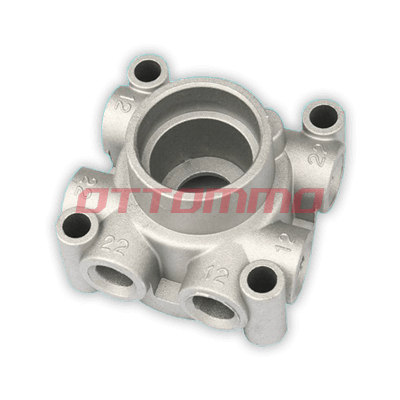

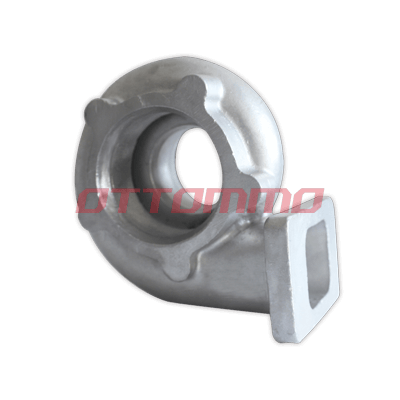

Die casting describes force the liquified metal under high pressure into multiple-use steel dies. After that, we get the raw casting after steel strengthens swiftly. This process is a fast as well as cost-efficient technique for high volume geometrically intricate components. In 2010, we developed the die casting plant as our joint endeavor. We intend to provide you top quality non-ferrous spreading components. Besides, we can full in-house CNC equipment, surface therapy as well as setting up.

Distinct Die Casting Process: We gained from previous 7 years. Many inquires of die cast parts called for machining and surface area treatment. Consequently, this makes our die casting distinct for you. From tooling/mold making to surface treatment and setting up, we take care of whatever for you in house.

Die Casting Capabilities: We have 3 stores in this plant: die actors store, tooling/mold shop and finishing/assembly store. Get in touch with us today and also you do not need to ask quotes from different places for a solitary component.

Distinct Die Casting Process: We gained from previous 7 years. Many inquires of die cast parts called for machining and surface area treatment. Consequently, this makes our die casting distinct for you. From tooling/mold making to surface treatment and setting up, we take care of whatever for you in house.

Die Casting Capabilities: We have 3 stores in this plant: die actors store, tooling/mold shop and finishing/assembly store. Get in touch with us today and also you do not need to ask quotes from different places for a solitary component.

Die casting is the method made use of for requiring liquified metal right into mold dental caries under high pressure. Die Casting is very versatile and thus, is the best made use of method for casting a metal. Die casting is like irreversible mold casting the only difference is that the steel is infused right into the mould at extremely high pressure of 10-210 Mpa. This results in a much more consistent component, generally good dimensional precision and excellent surface area coating.

The different steels and also alloys that can be used in die casting are zinc, aluminum, and copper, magnesium, tin as well as lead. Ferrous steels can also be made use of for die casting, die casting method is generally utilized for applications where a big quantity is medium or small sized components are needed with information, good dimension as well as fine surface area coating.

Advantages of Die Casting: The approach of die casting gives outstanding dimensional precision. The dimensional accuracy is comparable to 0.1 mm for the initial 2.5 cms and also 0.005 for the very first inch. Die casting likewise provides with smooth cast surface areas. Small and also thin wall surfaces and can be used the approach of die casting wall surfaces as tiny as 0.75 mm around can be casted. Inserts like thread insert Short article Submission, high stamina bearing surface areas and also burner could additionally be inserted using the Die Casting method. Die casting likewise aids in minimizing and even completely eliminating making use of additional machining procedures. The use of Die Casting method also aids to reduce the manufacturing time and also a massive number of short articles can be generated in a very short time. Die casting technique also helps to retain along with rise the tensile strength of the metal. It offers tensile stamina as high as 415 MPa that is 60ksi.

visit the website: click here