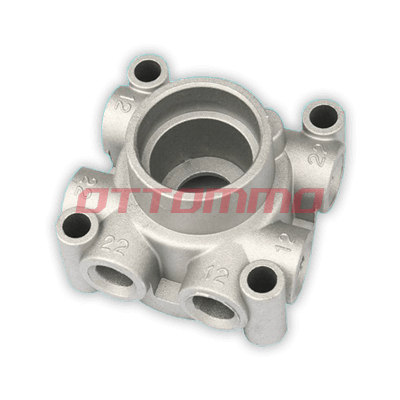

As we started as an investment casting foundry, we know details of this metal-forming strategy. Investment casting is additionally known as lost wax casting. Generally, it refers to make a wax pattern formed with a ceramic. Then, thawing the wax makes the ceramic empty. Ultimately we get the spreading after putting the metal right into the ceramic. We continuously improving our process and making use of the Iron Casting edge offered in our sector.

Water Glass as well as Silica Sol Investment Casting: Water glass and Silica sol spreading make china casting market unique throughout the globe. The major distinctions are the surface area roughness and also the casting price. Most factories made casting our of water glass procedure in China Ten Years earlier. Just few spreading shops change to silica sol procedure nowadays. However, we keep both procedures and also make more choices for our consumers.

Water Glass as well as Silica Sol Investment Casting: Water glass as well as Silica sol spreading make china casting industry special around the world. The major differences are the surface roughness and also the casting price. The majority of factories made casting our of water glass procedure in China Ten Years back. Just couple of casting factories transform to silica sol procedure nowadays. Nevertheless, we keep both procedures as well as make more alternatives for our clients.

Water Glass as well as Silica Sol Investment Casting: Water glass and Silica sol spreading make china casting market unique throughout the globe. The major distinctions are the surface area roughness and also the casting price. Most factories made casting our of water glass procedure in China Ten Years earlier. Just few spreading shops change to silica sol procedure nowadays. However, we keep both procedures and also make more choices for our consumers.

Water Glass as well as Silica Sol Investment Casting: Water glass as well as Silica sol spreading make china casting industry special around the world. The major differences are the surface roughness and also the casting price. The majority of factories made casting our of water glass procedure in China Ten Years back. Just couple of casting factories transform to silica sol procedure nowadays. Nevertheless, we keep both procedures as well as make more alternatives for our clients.

Silica Sol Investment Casting Approach: We utilize high temperature wax and dewax right into flash fire. On the other hand, ceramic mold and mildew material is silica sol zircon sand that is much more costly than quartz sand. As a result, the surface area finish as well as the accuracy of the spreading will certainly be very outstanding. Silica sol investment casting is our main production line right now.

Vacuum Casting: Vacuum casting ability makes it unique to you. We could make high quality and also facility castings by our vacuum cleaner furnace with affordable price. The only one distinction between regular investment casting and vacuum spreading is putting procedure. In order to attain optimal casting residential properties, we have to put the steel right into vacuum cleaner furnace. We thaw high nickel alloy or supper alloy and also pour the steel by evacuating air in an enclosed location. Consequently, we can attain complex and also difficult castings effectively.

visit us to know more us: click here

No comments:

Post a Comment