The Lost wax Casting process investment spreading process refers to a procedure where spreading of a reproduction sculpture can be done from a sculpture that is initial. Understood by a variety of names such as financial investment Iron Casting, accuracy. Other than that, artefacts have also been discovered in various other components of the world. Although the treatment has actually been customized according to current times, as well as varies according to shops, the conventional approaches are still preferred as well as the actions are standardized.

1.What's the process behind lost-wax spreading?

The casts are made from a duplicate of the original design, which might be made clay that is oil or wax-based. The moulds have external and inner moulds, right into which liquified wax is put to produce an even finishing over the internal surface area. Lost wax Casting process the external mould is made from plastic or fiberglass, while the inner mould is constructed of polyurethane rubber, latex, and also silicone. Moulds mainly contain 2 items in addition to a shim consisting of tricks, which are required to reconstruct the initial sculpt. After the poured-in wax cools as well as hardens, the mould acquires the favored thickness.

The wax version is after that eliminated from the mould, which might be used for making multiple models. A heat-resistant combination is after that poured right into the mould to blend out any problems, and also the shell is protected with many layers of the plaster. Various other molded pieces are currently attached to the main body. The design is upside down as well as baked in a kiln, which dries the plaster as well as the remaining wax runs out.

After eliminating remnant wetness, the shell is then loaded with sand and also molten steel is poured right into it. After it has cooled down, the covering and also the core are gotten rid of which reveals the initial spreading. The steel is now "gone after" to blend out problems, as well as the Lost wax Casting process now looks identical to the original version. The last casting is filed down and also ending up touches are included as needed.

2.What are the other uses Lost wax Casting process procedure?

1.What's the process behind lost-wax spreading?

The casts are made from a duplicate of the original design, which might be made clay that is oil or wax-based. The moulds have external and inner moulds, right into which liquified wax is put to produce an even finishing over the internal surface area. Lost wax Casting process the external mould is made from plastic or fiberglass, while the inner mould is constructed of polyurethane rubber, latex, and also silicone. Moulds mainly contain 2 items in addition to a shim consisting of tricks, which are required to reconstruct the initial sculpt. After the poured-in wax cools as well as hardens, the mould acquires the favored thickness.

The wax version is after that eliminated from the mould, which might be used for making multiple models. A heat-resistant combination is after that poured right into the mould to blend out any problems, and also the shell is protected with many layers of the plaster. Various other molded pieces are currently attached to the main body. The design is upside down as well as baked in a kiln, which dries the plaster as well as the remaining wax runs out.

After eliminating remnant wetness, the shell is then loaded with sand and also molten steel is poured right into it. After it has cooled down, the covering and also the core are gotten rid of which reveals the initial spreading. The steel is now "gone after" to blend out problems, as well as the Lost wax Casting process now looks identical to the original version. The last casting is filed down and also ending up touches are included as needed.

2.What are the other uses Lost wax Casting process procedure?

The lost-wax casting process has been made use of by foundry-men and also musicians to make intricate sculptures, accessories as well as automobiles for centuries. Aside from this, the procedure is likewise preferred for making spreading fashion jewelry, breastpins, clasps and also other tiny components required in numerous markets. Lost-wax casting can additionally be seen in textile usage, where the wax as well as textiles are replaced by steel when casting. Due to material reinforcement, the model is thinner which reduces the quantity of steel used in the mould.

3.What are the benefits of the lost-wax casting process?

Regardless of modern means of Lost wax Casting process, foundry-men as well as artists still choose the traditional methods of casting. A few of the benefits include –

a)The lost wax casting process procedure can be made use of on any type of material that can melt Lost and evaporate to leave a mould tooth cavity.

b)The duplicate design will certainly recreate even minute details of the initial sculpture.

c)Enables one-of-a-kind forms of casting that would be impossible in other methods.

Therefore, the Lost wax Casting process is a skilled approach for the recreation of various objects. Nonetheless, the procedure does have its drawbacks such as the first expense, require for large machinery and the particularity of openings in the mould. As a result, it is essential to look for know-how, layout, efficiency and cost to obtain the most effective quality at the best rate.

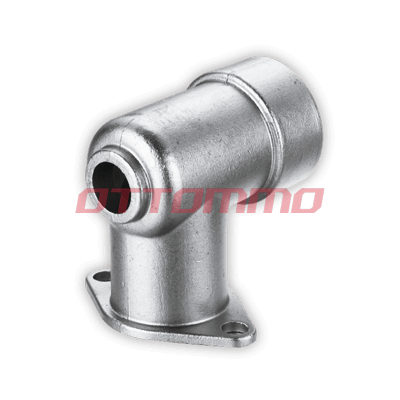

Ottommo.com is the Leading Makers and also Shop of Lost wax investment casting. We are likewise making Lost wax financial investment castings, steel spreading, precision investment casting items in China.

3.What are the benefits of the lost-wax casting process?

Regardless of modern means of Lost wax Casting process, foundry-men as well as artists still choose the traditional methods of casting. A few of the benefits include –

a)The lost wax casting process procedure can be made use of on any type of material that can melt Lost and evaporate to leave a mould tooth cavity.

b)The duplicate design will certainly recreate even minute details of the initial sculpture.

c)Enables one-of-a-kind forms of casting that would be impossible in other methods.

Therefore, the Lost wax Casting process is a skilled approach for the recreation of various objects. Nonetheless, the procedure does have its drawbacks such as the first expense, require for large machinery and the particularity of openings in the mould. As a result, it is essential to look for know-how, layout, efficiency and cost to obtain the most effective quality at the best rate.

Ottommo.com is the Leading Makers and also Shop of Lost wax investment casting. We are likewise making Lost wax financial investment castings, steel spreading, precision investment casting items in China.

No comments:

Post a Comment