Die casting is a process in which molten steel is forced under high pressure into mold tooth cavities. The steel sets to get a wanted form. In current times, plastic shaped components have replaced die-casting, as they are less costly and lighter than die cast components. Die-casting can be done utilizing a chilly chamber or hot chamber procedure. Die casting is a widespread non-expendable strategy in which steel are forced into the mold and mildew cavity under high pressure. Die casting mold and mildew that are referred to as dies can be made use of continuously to produce die Casting in a variety of dimensions, shapes and wall thickness. The mold and mildew dental caries are created with detailed styles that makes it possible for in producing intricate shapes with precision, surface Ductile Iron Casting as well as beauty.

In the very early days of die casting only low-pressure shot technique was utilized, however today high-pressure casting strategies like squeeze spreading and also semi-solid die casting techniques are utilized to cast more than 4500 pounds per square inch. At first, only tin and also lead were die caste, today magnesium, copper and also various other alloys are additionally to die casting using this very popular procedure.

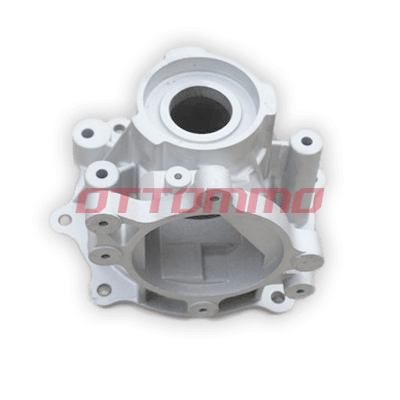

In this process molten metal or other products are forced, under high pressure into the tooth cavities of the steel mold and mildew. Passes away are 2 component mold and mildews that are constructed from alloy tool steel - The fixer pass away half and also the ejector die fifty percent. The die or mold and mildew is fabricated with the impression of the part that is to cast.

In the very early days of die casting only low-pressure shot technique was utilized, however today high-pressure casting strategies like squeeze spreading and also semi-solid die casting techniques are utilized to cast more than 4500 pounds per square inch. At first, only tin and also lead were die caste, today magnesium, copper and also various other alloys are additionally to die casting using this very popular procedure.

In this process molten metal or other products are forced, under high pressure into the tooth cavities of the steel mold and mildew. Passes away are 2 component mold and mildews that are constructed from alloy tool steel - The fixer pass away half and also the ejector die fifty percent. The die or mold and mildew is fabricated with the impression of the part that is to cast.

The liquified metal is infused right into the die under high pressure and also broadband, which assists in producing a casting that is smooth as well as precise as the original mold. The pressure is kept on the mold and mildew till the warm metal solidifies. When the steel is hardened, the die is opened to get rid of the casting.

Press spreading - An approach by which molten alloy is cast without turbulence and also gas entrapment at high pressure to produce top quality, thick, heat treatable components.

In modern day, advanced die casting machines are utilized that ensures constant quality assurance. Every machined die-casting differs in the technique in which liquified dish is poured into the die. Automations are utilized to lube dies, put the metal into the chamber, and so on. Two processes called the warm chamber as well as the cold chamber approaches are utilized for die casting.

Die casting is most suitable for casting tool sized get rid of intricate details. Die-casting is the biggest spreading strategy that is used to manufacture customer, industrial and industrial products like autos, playthings, parts of sink tap, port housing, equipments, and so on. A lot of die castings are done from non-ferrous steels like aluminum, magnesium, etc

.

No comments:

Post a Comment